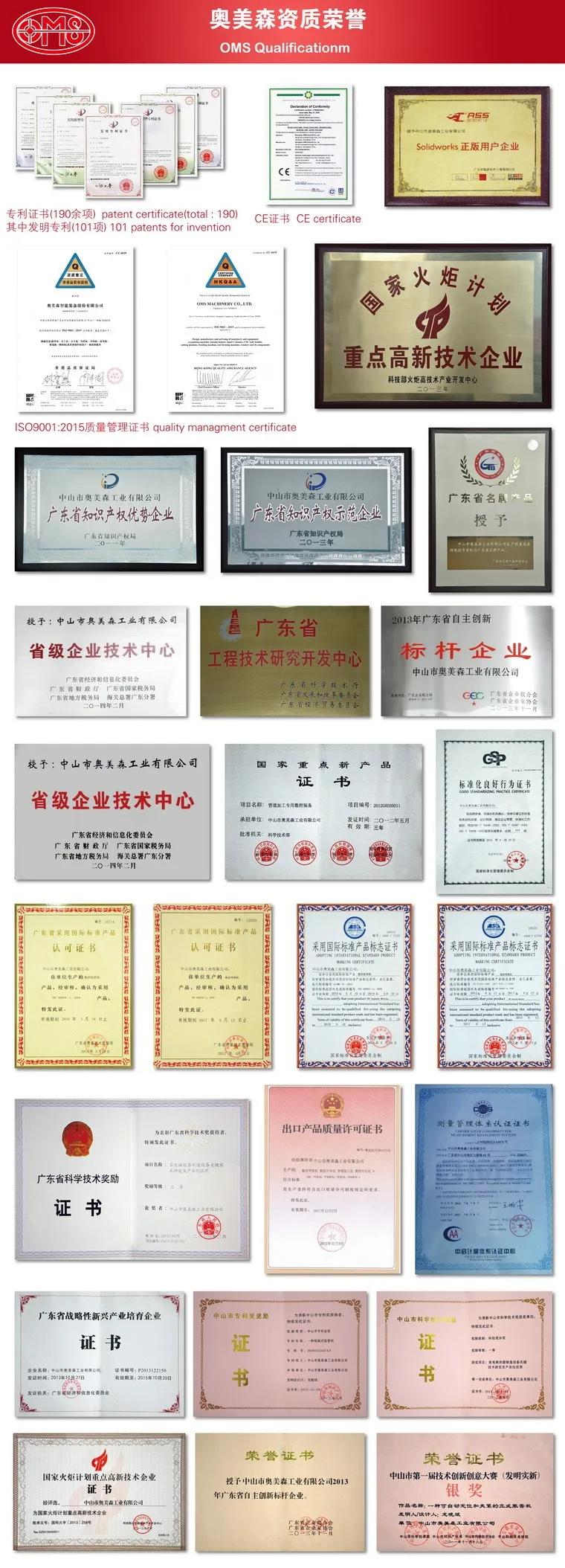

Brand Name: OMS

Model Number: CME7.94-60*5/2700L1F

Place of Origin: Guangdong, China (Mainland)

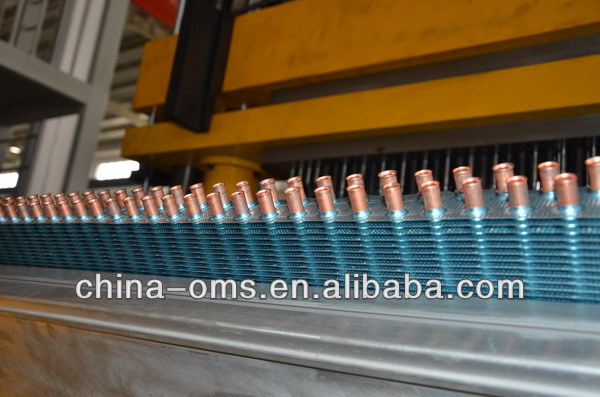

Tube expander

Tube expander is used to expand copper tubes inside heat exchanger coil so that copper tubes can contact the aluminum fins tightly to realize good heat exchange effects. The machine does expanding, flaring, and collaring automatically in one cycle, without the presence of the operator. It can also be used to expand aluminum tube coils.

Advantage:

The turn-over-door design enables the coil to be put in place for expansion automatically. The operator only has to load the coil to the door. The door will stand up, making the coil at vertical position and lock it for expansion. After processing, the door will lie down, so the operator can unload the coil at the horizontal level, and load the next coil. This is good for processing big coils, as it relieves the operators of heavy work.

Expanding, flaring, and collaring performed automatically in one cycle

Electric motor, low maintenance

High accuracy and efficiency.

| Technical parameter | ||||

| No. | Item | Content | ||

| 1 | Tube O.D | Φ7.94mm | ||

| 2 | Processing(hairpin) length | Max: 2700mm Min: 320mm |

||

| 3 | Coil alignment | 60holes *5rows | ||

| 4 | Hole pitch * Row pitch | 25mm*21.65mm | ||

| 5 | Coil loading mode | manual loading | ||

| 6 | Max tubes expanded simultaneously | 300 tubes/holes | ||

| 7 | Expanding force | Electric motor | ||

| 8 | Flaring mode | Group flaring | ||

| 9 | Flaring power | Electric motor | ||

| 10 | Tube length difference after expanding | ≤1mm when coil length≤1200mm ≤1.2mm when coil length>1200mm |

||

| 11 | Parallelism after expanding | ≤0.8mm when coil width≤800mm ≤2mm when coil length>1500mm |

||

| 12 | Cycle time | 30 seconds/cycle (when L=1000mm, not including load and unload) |

||

| 13 | Electric cabinent cooling | Air conditioner | ||

| 14 | Compressed air pressure | 0.4-0.6Mpa | ||

| 15 | Machine footprint | 5400*5050*9300(mm) | ||

| 16 | Total power | ≤30KW | ||

| Main components | ||||

| No. | Item | Brand | ||

| 1 | PLC | MITSUBISHI | ||

| 2 | Electrical components | Schneider ,SIMENS | ||

| 3 | Pneumatic components | FESTO, SMC | ||

| 4 | Light curtain | Banner(USA) | ||

| 5 | Inductive sensors | Schneider | ||

| 6 | Optic sensor | Schneider | ||

| 7 | Safety modules | Banner | ||

Packaging meets sea transportation standards, resistant against damp and rust.

We can send technicians and engineers abroad for machine installation, debugging, and maintenance.

OMS is professional manufacturer of CNC machinery, located in Zhongshan city, Guangdong, China. We design and manufacture automated equipment for air-conditioner heat exchanger production lines, such as hairpin bender, return bender, tube expander, condenser coil bender, and tube processing machines like tube bending, cutting, end forming machines, etc. Our machines are also widely used in the refrigerator, water heater, and automobile indurstries, and have been exported to over 40 countries

Our major customer: Gree, Haier, Midea, Daikin, Panasonic, Hitachi, Carrier, etc

We will attend China Refrigeration CRH2014 in Beijing. Our booth number is E3B66.